Conclusion

Coupled with Part 1 of the Achieving Circularity study, this report offers a pioneering vision for how to transform the Norwegian plastic system by 2040 to a circular, low-carbon model.

It demonstrates that durable applications are a highly effective use of plastics, providing benefits to society over a prolonged period of time and that, despite the many challenges and complexities, a more sustainable low-emissions circular system is feasible.

Circularity interventions can achieve unprecedented levels of resource efficiency across all sectors, and are an affordable, and scalable means of emissions reductions, therefore supporting sectors to grow whilst mitigating the key negative impacts of plastics (see Exhibit 35).

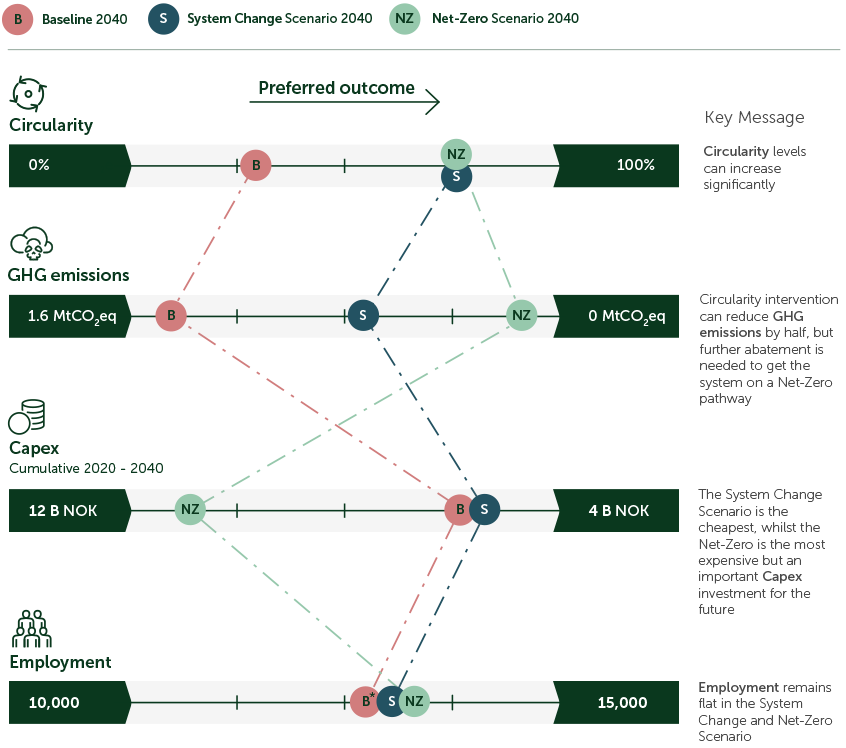

EXHIBIT 35

The System Change and Net-Zero Scenarios outperform the Baseline Scenario in circularity and GHG emissions, for an affordable investment, while keeping employment stable

The analysis shows the solution is not just about reusing and recycling, but also “rethinking” uses of plastic through new business models and dematerialisation. To realise this, the system requires a joint vision and strategy. The Norwegian plastics system faces an important decision on the role it plays in the global transition to high circularity and low emissions.

Norway has the opportunity to create the plastic system that is in harmony with the economy and the planet for future generations of Norwegians.

It can demonstrate to the world that this model is feasible – not just as a means of mitigating the negative effects of plastic on the climate, environment and human health, but as an exciting opportunity for growth and innovation in a thriving circular, net zero economy.

Contact

We would be happy to discuss or present the insights from the ‘Achieving Circularity’ studies in more detail. Please contact the team at [email protected]

Glossary

There is a glossary of terms used in this study available here >

Further Reading

This study is part of the Breaking the Plastic Wave series

Bibliography

- Häkkinen, Tarja, Kuittinen, Matti, Vares, & Sirje. Plastics in buildings. A study of Finnish blocks of flats and daycare centres. (2020).

- Statistics Norway. Dwellings, by type of building and utility floor space (M) 2007 – 2022. https://www.ssb.no/en/statbank/table/06513/.

- Geyer, R., Jambeck, J. R. & Law, K. L. Production, use, and fate of all plastics ever made. Science Advances 3, (2017).

- Hjellnes Consult. Plukkanalyser av restavfallskontainere fra byggeplasser. (2015).

- The Norwegian Ministries. Norwegian Plastics Strategy. (2020).

- International Resource Panel. Resource Efficiency and Climate Change: Material Effciency Strategies for a Low-Carbon Future. (2020).

- Plastics Europe. The Circular Economy for Plastics. (2019).

- Mepex. Materialstrømmen til plast i Norge – hva vet vi? (2020).

- Ingun Grimstad Klepp & Kirsi Laitala. Klesforbruk i Norge. (2016).

- Zero Waste Europe, Changing Markets Foundation & EEB. A new look for the fashion industry. (2021).

- Mepex. Assessment. (2019).

- Expert. Interview. (2022).

- Mepex. Collection and distribution of textiles in 2021, Textile Transparency Report 2021.

- McKinsey Apparel, Fashion & Luxury Group. Scaling textile recycling in Europe–turning waste into value. (2022).

- Baldé, C. P., Wagner, M., Iattoni, G. & Kuehr, R. In-depth review of the WEEE Collection Rates and Targets. 142 (2020).

- Baldé, C. P., Wagner, M., Iattoni, G. & Kuehr, R. In-depth review of the WEEE Collection Rates and Targets. 142 (2020).

- Circular Plastics Alliance. State-of-play on collected and sorted plastic waste – Electronics and Electrical Equipment. (2020).

- PolyCE. Circular guidelines for electrical and electronic equipment. (2020).

- Sam Pickard & Samuel Sharp. Phasing out plastics – The electrical and electronic equipment sector. (2020).

- OmBrukt. https://www.ombrukt.no/english/213184 (2021).

- Marc, J. Reuse of WEEE: widening the cycle of materials. Zero Waste Europe https://zerowasteeurope.eu/2011/12/reuse-of-weee-widening-the-cycle-of-materials/ (2011).

- Motorisation rates in the EU, by country and vehicle type. ACEA – European Automobile Manufacturers’ Association https://www.acea.auto/figure/motorisation-rates-in-the-eu-by-country-and-vehicle-type/ (2022).

- Automotive – The world moves with plastics (brochure) • Plastics Europe. Plastics Europe https://plasticseurope.org/knowledge-hub/automotive-the-world-moves-with-plastics-brochure/.

- European Commission. Factual Summary Report on the Public Consultation for the Impact Assessment of the Review of the Directive 2000/53/EC on End-of-Life Vehicles. https://ec.europa.eu/info/law/better-regulation/have-your-say/initiatives/12633-End-of-life-vehicles-revision-of-EU-rules/public-consultation_en (2022).

- MacArthur, E., Stuchtey, M. R. & Zumwinkel, K. Growth Within: A circular economy vision for a competitive Europe. https://emf.thirdlight.com/link/8izw1qhml4ga-404tsz/@/preview/1?o (2015).

- Circular Plastics Alliance. CPA Roadmap to 10Mt – Untapped Potential Report. https://ec.europa.eu/docsroom/documents/46956 (2021).

- Circular Plastics Alliance. Automotive WG input for Deliverable 2: Work plan on state of play collection and sorting. (2020).

- Borealis. Lightweight PP foams: Borealis helps build lighter vehicles using its expertise in the foam injection moulding process. Borealisgroup (en-GB) https://www.borealisgroup.com/polyolefins/automotive/lightweight-pp-foams-borealis-helps-build-lighter-vehicles-using-its-expertise-in-the-foam-injection-moulding-process

- Avient. Reducing Weight in Automotive Parts. https://www.avient.com/idea/reducing-weight-automotive-parts.

- Aigner, J. F., Broneder, C., Weibenbacher, J., Kuhnl, M. & Patz, C. Study: Plastic parts from ELVs. (2020).

- Fiskeridirektoratet. Fangst per fisker. Fiskeridirektoratet https://www.fiskeridir.no/Yrkesfiske/Tall-og-analyse/Fangst-og-kvoter/Fangst/Fangst-per-fisker (2022).

- Deshpande, P, Philis, G, Brattebø, H & Fet, Annik. Using Material Flow Analysis (MFA) to generate the evidence on plastic waste management from commercial fishing gears in Norway. https://reader.elsevier.com/reader/sd/pii/S2590289X19300210 (2019).

- Miljødirektoratet. Produsenter får større ansvar for produktene som avfall. Miljødirektoratet/Norwegian Environment Agency https://www.miljodirektoratet.no/aktuelt/nyheter/2022/november-2022/produsenter-far-storre-ansvar-for-produktene-som-avfall/ (2022).

- Marine Recycling Cluster. Practical solutions for a cleaner ocean. https://marinerecycling.no/ (2022).

- Berge, A. Verdens første havbruksmerd i resirkulerte materialer. iLaks https://ilaks.no/verdens-forste-havbruksmerd-i-resirkulerte-materialer/ (2021).

- Nordeide, S. Tar i bruk resirkulerte fôrslanger. iLaks https://ilaks.no/tar-i-bruk-resirkulerte-forslanger/ (2022).

- Nordeide, S. ScaleAQ med kommersiell satsing på gjenbruk av flytekrager. iLaks https://ilaks.no/scaleaq-med-kommersiell-satsing-pa-gjenbruk-av-flytekrager/ (2022).

- European Commission. Study on circular design of the fishing gear for reduction of environmental impacts. (Publications Office, 2020).

- Salt. Marin forsopling i norske fylker. (2022).

- DSolve. DSolve Annual Report. Annual Report 44 (2021).

- Norwegian Parliament. Norway’s long-term low-emission strategy for 2050. (2019).

- Climate Action Tracker. Climate Action Tracker Norway. https://climateactiontracker.org/countries/norway/ (2022).

- European Court of Auditors. Review No 4: EU action to tackle the issue of plastic waste. https://www.eca.europa.eu/Lists/ECADocuments/RW20_04/RW_Plastic_waste_EN.pdf (2020).