IN PARTNERSHIP WITH

Recycling of polyester textile waste in Europe can reach a breakthrough in scale and adoption – if policymakers and industry act decisively now.

Europe’s textile waste system is under pressure

Over 125 million tonnes of raw material are consumed by the global textiles industry each year – yet less than 1% of fibres are made from recycled textile waste. Most is landfilled, incinerated, or exported to regions ill-equipped to manage it responsibly. At the same time, Europe’s existing collection, sorting and reuse businesses models are struggling. Polyester, which accounts for ~57% of global fibre demand, is a key fibre type we need circular recycling solutions for.

A breakthrough is possible – if the right levers are pulled

The Textile Recycling Breakthrough is the first study to apply a tipping points framework to this challenge. Led by Systemiq, with input from a Steering Group comprising 17 organisations across the value chain, it presents the first detailed analysis of the cost gap between recycled polyester from post-consumer waste and virgin polyester from fossil fuels – and shows how Europe can lead on creating a competitive, circular textile industry – contributing to economic resilience, job growth and reductions in waste and greenhouse gas emissions.

RESOURCES

ANALYSIS BY

2025 annualised cost comparison of feedstock sources for polyester textiles

Kilotonnes

The technology is promising. The business case isn’t.

The study focuses on depolymerisation, a promising chemical recycling technology that can turn most polyester textiles from post-consumer waste back into top-quality fibre, with lower emissions than virgin production.

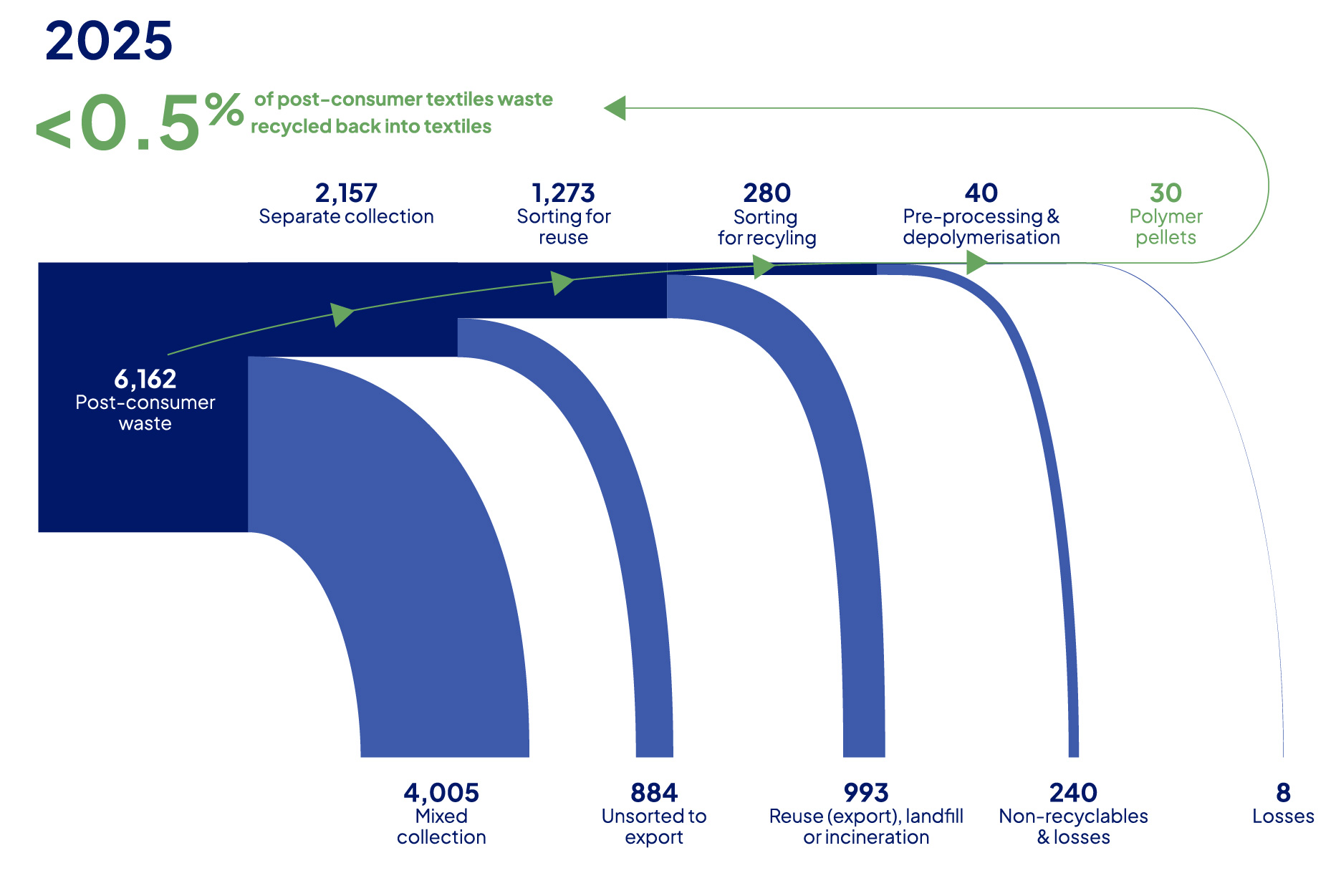

Yet today, following this process to make recycled polyester is estimated to cost ~2.6 times more to produce than virgin polyester from Asia, and less than 1% of the post-consumer textile waste feedstocks are accessible for this kind of recycling.

Four areas of intervention.

Ten levers for change.

To unlock scale and competitiveness, Europe must address barriers of both affordability and accessibility. The study identifies ten levers for policy and industry action across four areas of intervention: a) improving access to feedstock, b) strengthening offtake demand, c) reducing production costs, and d) leveling the remaining cost gap through EPR funding and green premia.

Reaching a tipping point.

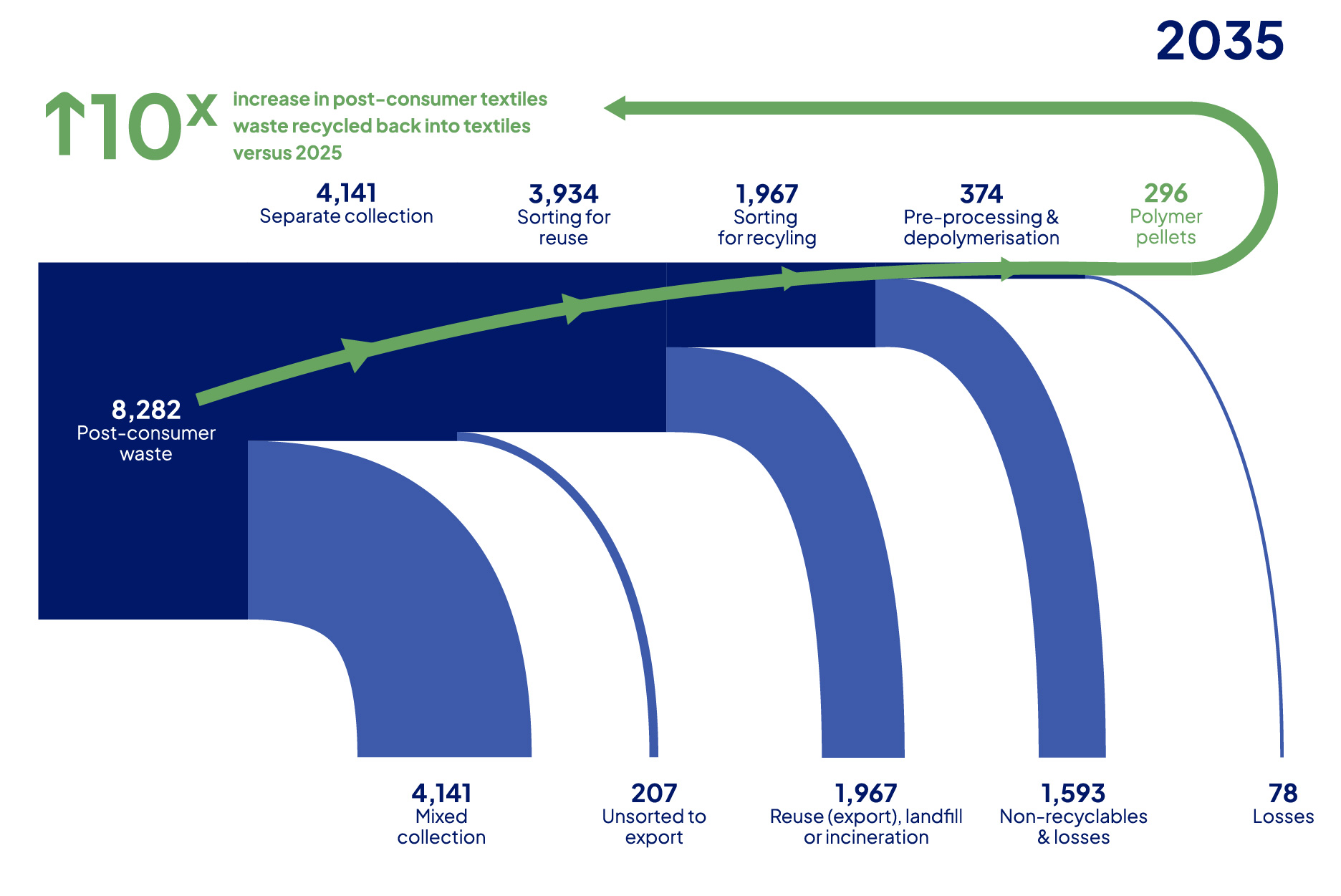

With these interventions, Europe could reach a tipping point – where recycled polyester from post-consumer waste becomes more accessible, affordable and attractive than virgin alternatives. As a result, depolymerisation capacity could grow nearly tenfold by 2035 – helping reduce the fashion sector’s environmental impact by cutting waste and emissions and reducing dependence on virgin raw materials.

EU textile post-consumer waste recycling:

A comparison of 2025 and 2035 volume flows

Kilotonnes

2035 annualised cost comparison after application of ten levers

€/tonne of end product

Closing the remaining cost gap.

The report proposes an EPR (Extended Producer Responsibility) fee in the direction of €250–330/tonne on polyester put on the EU market to cover the net costs of collection, sorting, and recycling in a scaled system. A ~5% brand-level green premium would cover shipping costs to Asian supply chains and close the remaining cost gap. Together, these support mechanisms add up to around €0.15 for a 400g polyester jumper.

However, the report adds that, while building a viable recycling system is critical, a truly circular textile economy will require deeper changes in how we design, produce, consume, and value clothing.

The socio-economic opportunity.

A related Systemiq study showed that a broader system change across PET packaging and polyester textiles – combining depolymerisation and mechanical recycling, reduction and reuse – could generate €5.5 billion in annual value and create 28,000 net new jobs in Europe’s recycling sector by 2040.

Circularity beyond recycling.

However, the report adds that, while building a viable recycling system is critical to dealing with the waste we inevitably produce, a truly circular textile economy will require deeper changes in how we design, produce, consume, and value clothing.

ACKNOWLEDGEMENTS

The Textile Recycling Breakthrough was funded by grants from Arc’teryx, Eastman, Interzero, Textile Exchange, and Tomra. It was guided by an independently chaired Steering Group representing industry, civil society, and academia, ensuring its independence and rigour.