Chapter 1

The current state of play

Plastic has been a key enabler of accelerated growth across all five sectors in scope of this study (Construction, Textiles, Electronics, Automotive, and Fishing and Aquaculture) over the last decades due to its affordability, durability, low weight, high resistance, and potential to mould and shape into any design. At the same time, it is these characteristics that are also creating the environmental and social problems related to the current plastic system, a high greenhouse gas (GHG) emission system that – without the right treatment at end-of-life – also causes plastic pollution that damages the environment and potentially human healthc.

For Norway, the biggest issue is the large amount of GHG emissions generated by the plastic systemd. Fossil based plastic manufacturing processes and incineration of plastic waste, which is the primary pathway for plastics used in Norway, emit a significant amount of GHGs and this is projected to increase between now and 2040. Domestic plastic pollution also exists but is less significant than in other markets, although Norway does not have full control over the fate of almost 40% of its plastic waste as it is currently exported overseas.

A very diverse set of durable plastic systems

This study includes a varied and complex set of product categories across very different sectors, ranging from consumer electronics like mobile phones, to industrial fishing nets, and fuel tanks in cars (see Exhibit 2).

Although solutions should be tailored to meet the unique needs of each of these product applications, they all face similar challenges given that all the product categories in scope are durable, with average lifetimes ranging from 2 years for certain garments to 35 years for plastics in construction.

Key challenges include:

Inadequate regulation, with plastic not being a priority compared to other materials used in the sector. For example, there are no plastic-specific circularity targets for Automotive and Construction and existing waste targets can be met by focusing on other materials.

Product design not factoring in end-of-life treatment, resulting in a decline of recyclability and recoverability of materials from mixed material streams in a market with insufficient collection, sorting and recycling infrastructure.

For some sectors, inefficient use of plastic is exacerbated by the low cost of virgin plastics and the lack of alternative business models to increase utilisation, including better access to collection or incentives to hand in used products (e.g. clothes accumulating in wardrobes after several wears, electronics not handed in, underutilisation of cars).

EXHIBIT 2

Sectors in scope are very diverse in terms of plastic usage, content and lifetimes

A greenhouse gas intensive and highly linear starting point

In 2021, the plastics in the five sectors analysed represented about ~46% of total annual demand and ~25% of total annual waste of plastic in Norway.

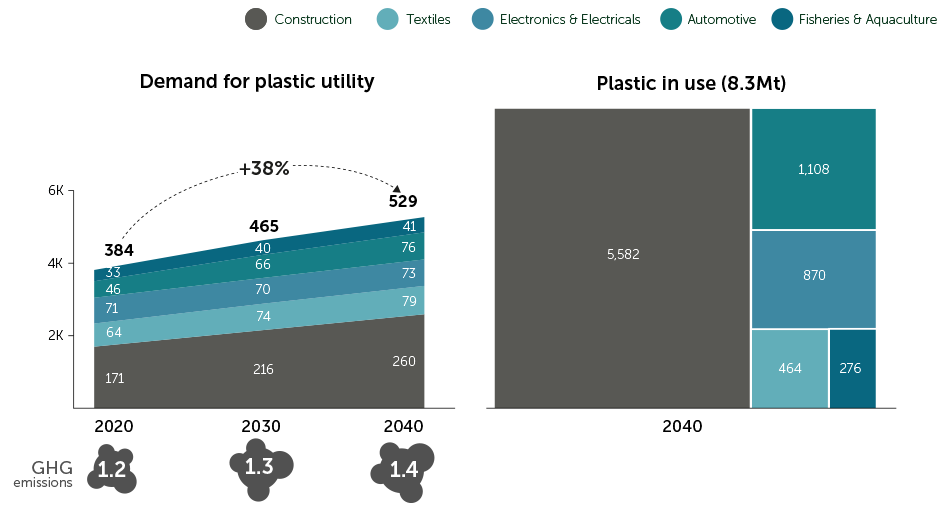

Annual demand is predicted to grow by ~38% by 2040 and this will lead to an almost 70% increase in the volume of plastic accumulated in the system, rising to ~8,300 tonnes by 2040, representing the lion’s share of plastic in stock.

Around 90% of this will be virgin plastics, and combined with increased incineration, will result in an increase of GHG emissions from 1.2 million tonnes of carbon dioxide equivalent (CO2eq) in 2020 to 1.4 million tonnes of CO₂eq by 2040, instead of the declining emissions pathway needed during this period.

“A declining emissions pathway is urgently needed to stop the growing GHG emissions in Norway.”

EXHIBIT 3

As demand for plastic utility continues to grow, accumulation of plastic in use will grow to 8.3Mt by 2040

Baseline Scenario

Kt*, Mt CO2eq**

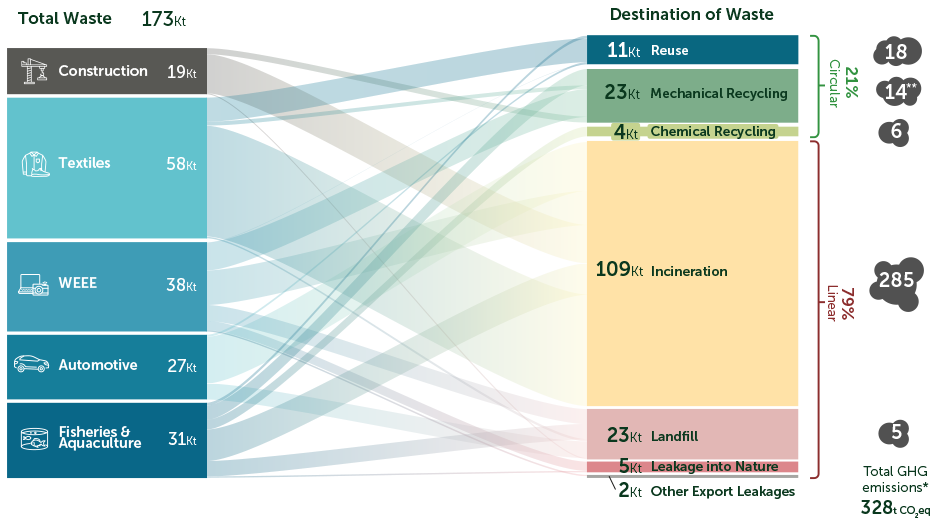

Today, plastics use across the five sectors is still highly linear (~79%), with the predominant pathway being fossil based plastic manufacturing processes with incineration at end-of-life (~63%) (see Exhibit 4). This has significant implications, including:

- Incineration is a highly emissions and resource inefficient destination, which will continue to scale as the plastic system grows. The climate crisis makes the operating model of extraction, production and burning completely untenable. Long-term capex and feedstock lock-ins of incinerators make it more challenging to promote a circular system.

- With durables, especially the ones with very long lifetimes, there is a risk of shifting responsibility for large waste volumes, which are operationally and economically challenging to address, to the next generation.

- Several sectors, notably Waste from Electrical and Electronic Equipment (WEEE) and Fisheries & Aquaculture, have non-trivial plastic leakage into naturee, but data availability remains a challenge. However, broadly speaking, direct leakage is less of a challenge in the Norwegian system than in some less developed countries.

In terms of circular destinations (i.e. reduction, reuse and recycling), the main solutions currently revolve around recycling (~15%). However, this is predominantly open loop recycling and therefore plastic is not kept in use in the same sector and is not considered recyclable thereafter.

Finally, for both circular and linear end-of-life destinations, the five sectors depend heavily on exports (~36%) – meaning that Norway has less control over the system (e.g. little visibility of reuse of clothes outside the EU) and causing additional adverse impacts (e.g. transportation emissions during export and import).

EXHIBIT 4

Today the most common fate of most domestic and exported plastic waste is incineration, causing significant GHG emissions

Baseline Scenario 2020 Kt / tCO2eq

Momentum for change is building but current commitments are falling short

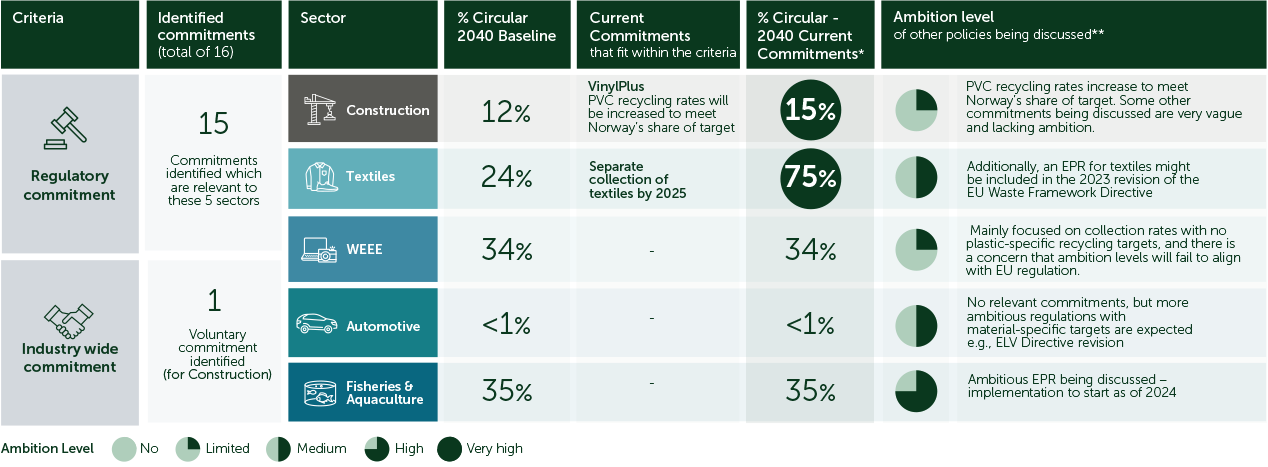

While current commitments to cut plastic waste are building momentum, and more ambitious Norwegian policies are being discussed, they are falling far short of achieving a low-emissions, zero-waste circular plastic economy.

In this study, we identified 16 policies and industry commitments (see Exhibit 5). However, only two of these fit the criteria for inclusion in our Baseline “Current Commitments” Scenario,

having been confirmed and with strict concrete targets and roadmaps already in place: the separate collection of textiles by 2025, and the PVC collection targets in construction set by VinylPlus.

If met, these current commitments result in an increase in system circularity of durables from 21% today to 31% by 2040.

“Current commitments are falling short to deal with the accelerating rise in waste volumes combined with the escalating GHG emissions”

EXHIBIT 5

Only two commitments identified met the criteria to be included in the Current Commitment Scenario implying that a significant raise in policy ambition is required across all sectors

A qualitative assessment, in which we also consider upcoming regulations and commitments, shows that the regulations being discussed for Fisheries & Aquaculture and Textiles are the most ambitious among the sectors analysed, and include an extended producer responsibility (EPR) framework. In contrast, the Norwegian regulations for the Construction and Automotive sectors are falling short as their current focus is on other materials. However, more ambitious regulations with material-specific targets are expected, for example the End of Life Vehicle Directive revision. Finally, Norway’s WEEE regulations are mainly focused on collection rates with no plastic-specific recycling targets and there is a concern that ambition levels will fail to align with EU regulation.

Experts believe that new policies, particularly EPR, will be key to accelerating the transition to circularity.

Scenarios modelled

With the Current Commitments context as a starting point, we modelled two additional scenarios, and quantified their economic, environmental, and social implicationsf:

- A System Change Scenario, in which we applied circularity interventions to analyse what is the most ambitious level of circularity that can be reached by 2040.

- A Net-Zero Scenario, in which we applied GHG emissions reduction technologies to the plastics value chain, following the application of circularity interventions.